With the rapid development of infrastructure construction, the market demand for sand and gravel aggregates has also increased sharply. At present, there are two main sources of sand and gravel aggregates, one is natural sand and the other is artificial sand. With the gradual depletion of natural sand, the market for artificial sand is growing. More and more investors are investing in suitable equipment to produce artificial sand.

At present, there are mainly two types of stone crushing production lines: mobile crushing plant and stationary crushing plant. So, what is the difference between these two crushing plants, and how should investors choose? This article will introduce the features and advantages of these two types of crushing plants in order to help you choose a right one.

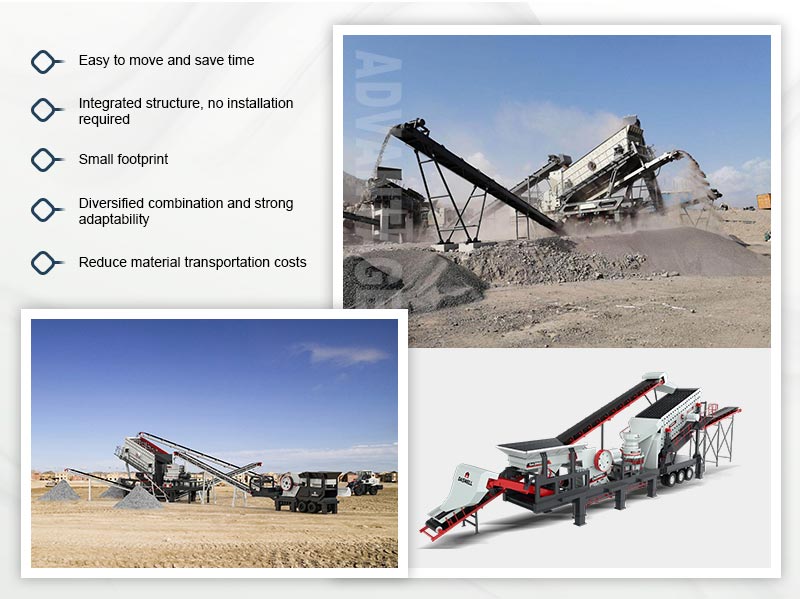

Mobile crushing plant

Mobile crushing plants are mostly used for material processing in metallurgy, chemical industry, building materials, hydropower and other frequently relocated projects. At present, it is mainly used for the processing of construction waste in urban demolition. It can crush and screen construction waste into aggregates of different specifications and sizes, so as to realize the recycling of construction waste.

Mobile crushing plant can be divided into two types, crawler type and tire type. The difference between the two is mainly in the way of walking. The tire type crushing plant needs a trailer as traction when walking, while the crawler type crushing plant needs no traction and can be moved by using the crawler.

Advantages

Easy to move and save time. Different crushing equipment is installed on an independent movable chassis to form a mobile crushing plant, which can move quickly between different sites and save transition time.

Integrated structure and no installation required. The integrated structure reduces the complicated installation process. After the mobile crushing plant arrives at the construction site, the work can be carried out quickly, reducing the work intensity and saving installation time.

Small footprint. The main equipment of the mobile crushing plant is concentrated on its mobile frame, which has a compact structure and a small footprint, which is suitable for projects with limited construction sites.

Diversified combination and strong adaptability. Mobile crushing plants are available in various configurations. The manufacturers can form a process flow of "first crushing and then screening" or "first screening and then crushing" according to user needs. In addition, the crushing plants can also be combined into a two-stage crushing system of coarse and fine crushing, or can be combined into a three-stage crushing system of coarse, medium and fine crushing.

Reduce material transportation costs. The mobile crushing plant can process materials on site without having to move the materials away from the site and then crush them, which greatly reduces the transportation cost of materials.

Disadvantages

Compared with the stationary crushing plant, the price of the mobile crushing plant will be slightly higher. If your investment cost is sufficient and the construction site is limited, the mobile crushing plant is an ideal choice. In addition, the maintenance cost of mobile crushing plants is relatively high.

Because of the limited space and load-bearing capacity of the mobile crushing plant frame, it is more suitable to configure small and medium-sized crushers. If you have higher production requirements, you may need to increase your investment cost.

In addition, if your project has multiple mining sites, you need to configure multiple mobile crushing plants to operate simultaneously.

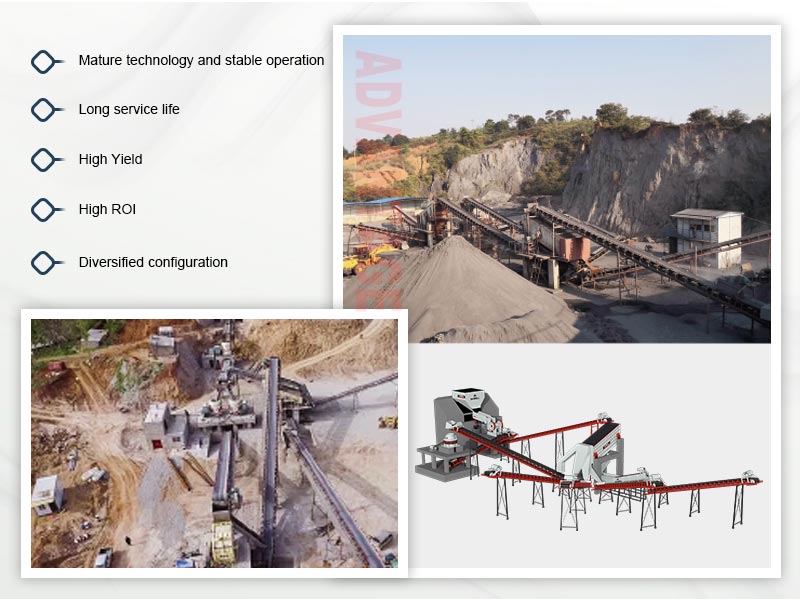

Stationary crushing plant

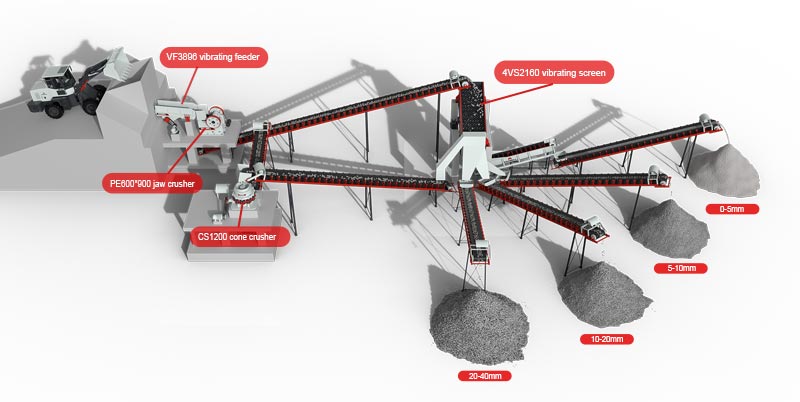

The stationary crushing plant is mainly a complete production line combined with feeder, jaw crusher, cone crusher, impact crusher, vibrating screen, sand washer, belt conveyor and other equipment. It is a traditional sand processing process, mainly suitable for projects with large production scale, long production cycle and no need to transfer.

According to the different requirements of customers, manufacturers can customize stationary crushing production lines for customers. The stationary crushing plant is mainly used for mining and crushing of various mines.

Advantages

The technology is mature and the operation is stable. Whether installation or operation, the technology of stationary crushing plant is very mature. After training, the operator can quickly master the relevant operating skills. The equipment is of reliable quality and stable operation.

Long service life. Once the stationary crushing plant is successfully installed and put into use, it only needs regular maintenance. The maintenance is simple, the failure rate is low and the service life is long.

High output. The stationary crushing plant is less restricted by space and can be equipped with large size crushers, which improves the output and caters to the needs of large project production.

High return on investment. Relatively speaking, the production efficiency of stationary crushing plant is higher. After the equipment is put into use, it can run continuously and realize automatic production to obtain higher returns.

Diversified configuration. There are various types of crushers, including jaw crusher, cone crusher, impact crusher, hammer crusher, vertical shaft impact crusher, etc. These crushers can flexibly form different stationary crushing plants to meet the needs of different customers.

Disadvantages

The stationary crushing plant occupies a large area and has higher requirements on the site. Moreover, before installing the stationary crushing plant, it is necessary to construct concrete foundations, steel frame foundations, etc., which requires a lot of time and manpower. In addition, after the mining is completed, the original infrastructure cannot be reused.

Mining and other projects are generally located in relatively remote locations, and the raw materials require a lot of manpower to be transported to the construction site with the aid of auxiliary equipment. This increases the corresponding production cost.

02 Comments

Lorem ipsum, dolor sit amet consectetur adipisicing elit. Dicta perferendis asperiores voluptatum saepe repellat atque obcaecati dolores nulla, explicabo harum inventore sed corrupti molestiae aspernatur.

Lorem ipsum dolor sit amet consectetur, adipisicing elit. Qui expedita magnam ea tempora consectetur fugit dolorum numquam at obcaecati voluptatibus.

Lorem, ipsum dolor sit amet consectetur adipisicing elit. Error, ipsa dolor exercitationem culpa obcaecati illo veniam voluptatem perferendis hic nisi tempora omnis, mollitia unde doloribus.